This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

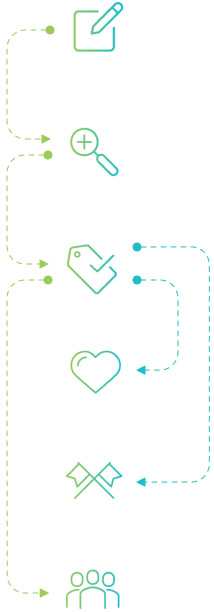

Reverse Logistics – Monitoring Life-Cycle of Products

But What is Reverse Logistics?

Reverse logistics refers to the practice of returning (or recycling) goods from a customer to a seller or a manufacturer. The efficiency of a company’s reverse logistics process directly impacts customer satisfaction and customer retention. Thus, to build customer trust, organizations must move goods from end customers back to their possession and then to their suppliers. However, this practice is a trillion-dollar problem, which, if not managed properly, may incur substantial costs for businesses. Unilog is a team of professionals that can help businesses to manage their reverse logistics better.