Digital Supply Chain Control Tower

Digital Supply Chain is the next-generation solution that implements the Internet of Things, advanced robotics, and big data analytics in supply chain management: “Place sensors everywhere, construct networks, automate, and analyze all the processes to increase performance and customer satisfaction.

Supply Chains: Traditional vs. Digital

Traditional supply chains use strategy to plan and react while digital supply chains predict and prescribe actions to take. Traditional supply chains are mostly static and operate on rules based on prior transactional inputs, while completely digital supply chains operate in real time and can quickly adapt to changing conditions.

Digital supply chains are networks as opposed to the linear nature of traditional supply chains. While digital supply chains integrate data from operational technology and IT systems, traditional supply chains frequently rely on isolated systems.

With a digital supply chain, shared quality and control data from the supplier allows organizations to foresee concerns and respond proactively without the need for costly prior planning. The planning and management of all sourcing and procurement, conversion, and logistics management tasks are all included in supply chain management. This entails coordination and cooperation with all parties involved, including as customers, suppliers, and middlemen.

Five advantages of implementing a digital supply chain strategy

Digital supply chain management is based on IT technologies, connectivity, data, and advanced analytics. Unilog provides opportunity to combine these components together and brings about the following advantages, especially when all partners along the value chain adopt them:

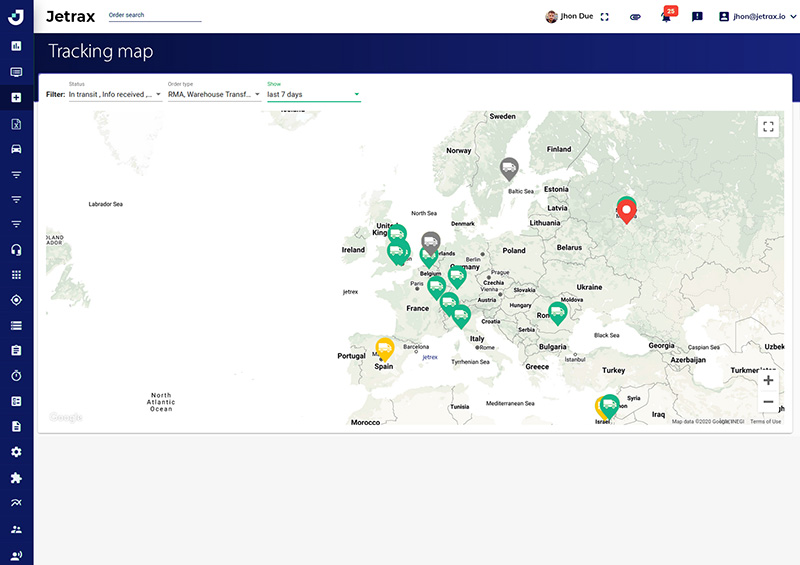

Improved Monitoring of Supply Chain Performance

A digital supply chain offers substantially more visibility into its constituent pieces and moving parts than do traditional supply networks. With real-time visibility into supplier performance, organizations are better able to spot any gaps that could lead to disruptions and fix them.

Digital supply chains are also more focused on the demands of the client, allowing businesses to better comprehend those needs and take steps to enhance customer experiences.

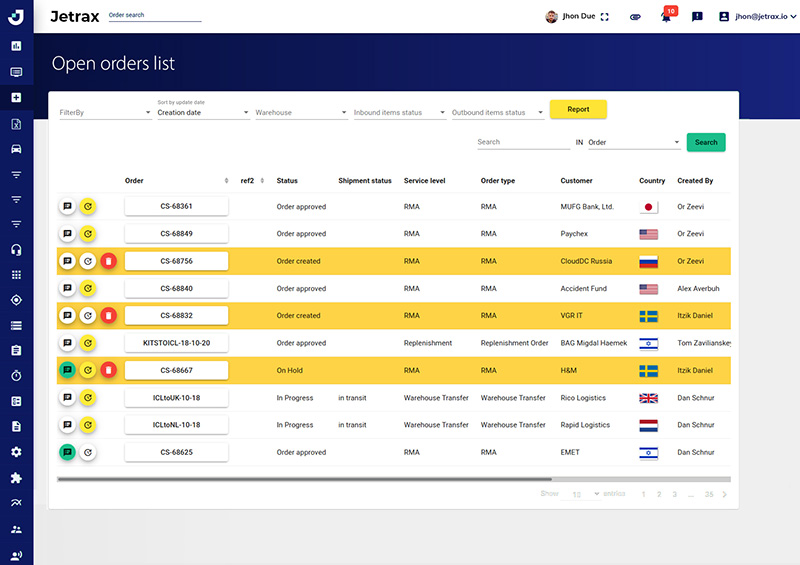

Automation of Processes

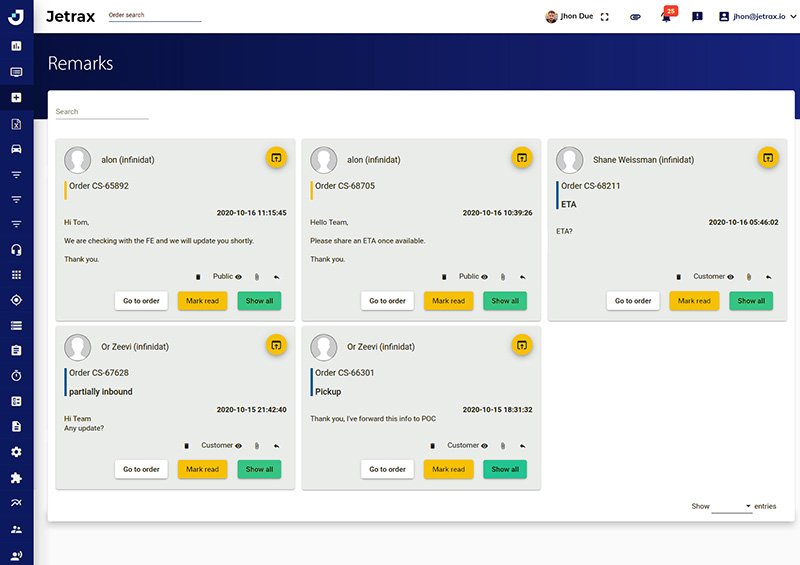

Traditional paper-based, manual supply chain procedures are done away with in a digital supply chain. Stakeholders no longer have to call or email for updates or perform manual data entry. Whoever requires it has easy access to all the data they need to enhance their operations and work with other organizations.

Business processes are automated as a result of digitalization, which enhances worker performance, productivity, and profitability. Sensors and other digital instruments enable real-time inventory tracking throughout the whole supply chain. In the end, electronic connectivity enables businesses to redefine new business strategies and optimize the supply chain.

Minimize expenses and accelerate innovation

Modern, comprehensive information regarding performance, condition, and requirements is provided by a digital supply chain. Processes such as raw material flows, operational logistics, inventory levels, forecasting, and resource planning may all be managed and optimized with the use of this data. These are the immediate advantages of increased cash flow and expense savings.

The opportunity to detect process bottlenecks, shorten time, speed up innovation, and boosting the return on investment are possible only through improved information sharing and cooperation.

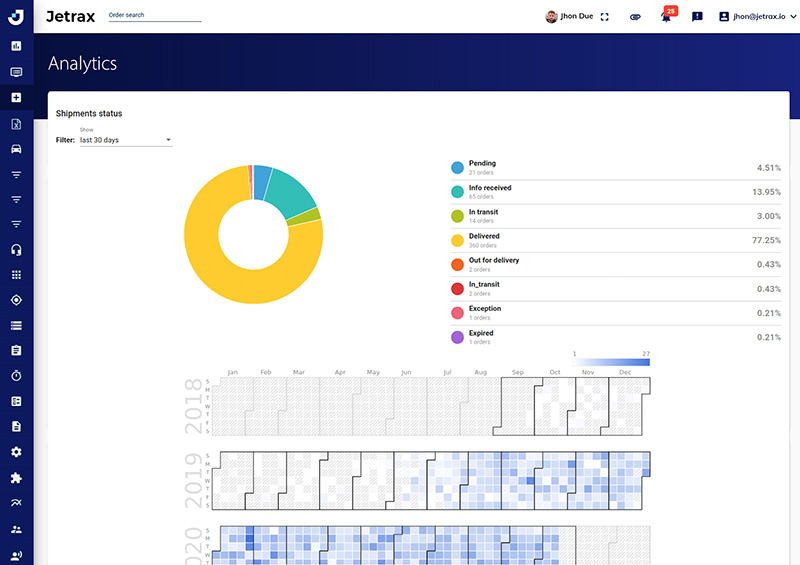

Advanced Analytics and Statistics

Numerous data-driven technologies, such as big data, machine learning, IoT, and predictive analytics, support the digital supply chain. To enhance inventory management and preventative maintenance, organizations can link and relate data sources. They may use data to find inefficiencies, improve the quality of their products, and improve consumer experiences.

Advanced analytics with data visualization can also be offered by a digital supply chain, enabling users to make predictions, learn from past mistakes, and make better decisions.

Plan the supply chain more effectively

In standard supply chains, it can be difficult, time-consuming, and unreliable to identify potential problems and estimate their likely repercussions. Companies in a digital supply chain can foresee problems and take swift action before the situation worsens thanks to shared and current quality and control data.

In order to enhance the performance of the end-to-end value chain, businesses can better coordinate and interact with a variety of stakeholders through the use of digital tools and technology, including vendors, customers, and third-party service providers.

The traditional supply chain management paradigm is transformed into a digital supply chain by incorporating cutting-edge electronic and digital technology. Unilog can offer your companies to implement these technologies:

– Cloud computing

– Software as a service (SaaS) / Supply chain as a service (SCaaS)

– Big data

– Artificial intelligence

– Internet of things (IoT)

– Application Programming Interface

Being involved in the supply chain industry at this time is exciting. Make sure that the way of digitizing your supply chain will be smooth and fascinating with our Unilog Team. Because of all these fantastic technologies, there will be incredible chances to influence and take part in the transition to a world of digital supply chains.