This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Distribution Management

What Is Distribution Management?

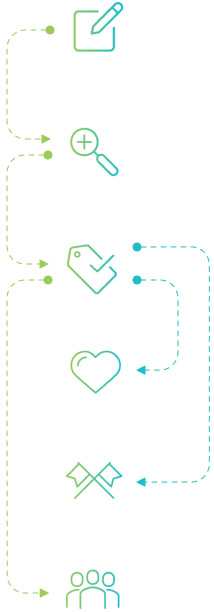

Distribution management is a process that controls the path of goods from the manufacturer to the consumer. The method of delivering goods from the manufacturer to the customer is relatively straightforward, however, if suppliers, distributors, and retailers are involved in the process, the path becomes more complex, and in this case, distribution management is necessary to ensure the delivery of goods to the customer on-time.

Distribution management includes various processes consisting of raw material supplier management, packaging, warehousing, inventory, supply chain, and logistics; in other words, all the necessary functions for high-quality and safe transit of goods to their destination.

First of all, proper management of the distribution of goods ensures the uninterrupted business delivery of goods or services to the customer; poor-quality processes lead to customer dissatisfaction and affect the company’s image.